All Categories

-

Discrete Semiconductor Products

Discrete Semiconductor Products

- IGBT Modules(68343)

- Transistors - Special Purpose(64)

- Transistors - Programmable Unijunction(1584)

- Transistors - JFETs(1690)

- Transistors - IGBTs - Single(6032)

- Transistors - IGBTs - Modules(1087)

- Transistors - IGBTs - Arrays(9)

- Transistors - FETs, MOSFETs - Single(16037)

- Transistors - FETs, MOSFETs - RF(3251)

- Transistors - FETs, MOSFETs - Arrays(6376)

- Transistors - Bipolar (BJT) - Single, Pre-Biased(4478)

- Transistors - Bipolar (BJT) - Single(12624)

- Transistors - Bipolar (BJT) - RF(488)

- Transistors - Bipolar (BJT) - Arrays, Pre-Biased(6311)

- Transistors - Bipolar (BJT) - Arrays(1394)

- Thyristors - TRIACs(1128)

-

RF/IF and RFID

RF/IF and RFID

- RFI and EMI - Shielding and Absorbing Materials(8538)

- RFI and EMI - Contacts, Fingerstock and Gaskets(4004)

- RF Transceiver Modules(4056)

- RF Transceiver ICs(1553)

- RF Switches(8107)

- RF Receivers(639)

- RF Receiver, Transmitter, and Transceiver Finished Units(3515)

- RF Mixers(4622)

- RF Misc ICs and Modules(2738)

- RF Evaluation and Development Kits, Boards(1994)

- RF Directional Coupler(2963)

- RF Antennas(7488)

- RF Amplifiers(17487)

- Attenuators(3204)

-

Optoelectronics

Optoelectronics

- Panel Indicators, Pilot Lights(47475)

- Optics - Light Pipes(3353)

- Optics - Lenses(15458)

- LEDs - Spacers, Standoffs(433)

- LEDs - Circuit Board Indicators, Arrays, Light Bars, Bar Graphs(1922)

- LED Lighting - White(13461)

- LED Lighting - Color(2210)

- LED Lighting - COBs, Engines, Modules(9508)

- LED Indication - Discrete(10227)

- Lamps - Incandescents, Neons(338506)

- Infrared, UV, Visible Emitters(3759)

- Fiber Optics - Transceiver Modules(22925)

- Display Modules - LED Character and Numeric(2162)

- Display Modules - LCD, OLED, Graphic(3487)

-

Sensors, Transducers

Sensors, Transducers

- Temperature Sensors - Thermostats - Mechanical(4379)

- Temperature Sensors - NTC Thermistors(7932)

- Temperature Sensors - Analog and Digital Output(2963)

- Proximity Sensors(3322)

- Pressure Sensors, Transducers(10275)

- Position Sensors - Angle, Linear Position Measuring(3882)

- Optical Sensors - Photointerrupters - Slot Type - Transistor Output(513)

- Optical Sensors - Photointerrupters - Slot Type - Logic Output(559)

- Optical Sensors - Photoelectric, Industrial(12132)

- Optical Sensors - Photo Detectors - Remote Receiver(1350)

- Magnetic Sensors - Switches (Solid State)(1519)

- Magnetic Sensors - Position, Proximity, Speed (Modules)(2148)

- Encoders(3440)

- Current Transducers(2256)

-

Connectors, Interconnects

Connectors, Interconnects

- Terminal Blocks - Wire to Board(19352)

- Terminal Blocks - Headers, Plugs and Sockets(148192)

- Terminal Blocks - Barrier Blocks(44736)

- Sockets for ICs, Transistors(2223)

- Rectangular Connectors - Housings(28877)

- Rectangular Connectors - Headers, Receptacles, Female Sockets(23450)

- Rectangular Connectors - Headers, Male Pins(138439)

- Rectangular Connectors - Free Hanging, Panel Mount(15074)

- Rectangular - Board to Board Connectors - Board Spacers, Stackers(27782)

- Rectangular - Board to Board Connectors - Arrays, Edge Type, Mezzanine(14186)

- D-Sub Connectors(106471)

- Circular Connectors - Housings(221760)

- Circular Connectors(771637)

- Card Edge Connectors - Edgeboard Connectors(497865)

- Backplane Connectors - Specialized(33926)

-

Resistors

-

Capacitors

Capacitors

- Trimmers, Variable Capacitors(1088)

- Thin Film Capacitors(1724)

- Tantalum Capacitors(79518)

- Tantalum - Polymer Capacitors(2486)

- Silicon Capacitors(225)

- Niobium Oxide Capacitors(128)

- Mica and PTFE Capacitors(908)

- Film Capacitors(89898)

- Electric Double Layer Capacitors (EDLC), Supercapacitors(1644)

- Ceramic Capacitors(261123)

- Capacitor Networks, Arrays(740)

- Aluminum Capacitors(39501)

- Aluminum - Polymer Capacitors(2396)

-

Transformers

-

Isolators

-

Crystals, Oscillators, Resonators

-

Switches

Switches

- Toggle Switches(18713)

- Thumbwheel Switches(1050)

- Tactile Switches(9157)

- Snap Action, Limit Switches(14916)

- Slide Switches(24680)

- Selector Switches(4460)

- Rotary Switches(5818)

- Rocker Switches(60676)

- Pushbutton Switches - Hall Effect(3768)

- Pushbutton Switches(29541)

- Programmable Display Switches(13202)

- Navigation Switches, Joystick(14105)

- Magnetic, Reed Switches(604)

- Keypad Switches(168067)

- Keylock Switches(1623)

-

Relays

-

Integrated Circuits (ICs)

Integrated Circuits (ICs)

- Specialized Hot ICs(1019687)

- Specialized ICs(35707)

- PMIC - Voltage Regulators - Special Purpose(1598)

- PMIC - Voltage Regulators - Linear Regulator Controllers(572)

- PMIC - Voltage Regulators - Linear + Switching(499)

- PMIC - Voltage Regulators - Linear(27467)

- PMIC - Voltage Regulators - DC DC Switching Regulators(20868)

- PMIC - Voltage Regulators - DC DC Switching Controllers(4728)

- PMIC - Voltage Reference(2128)

- PMIC - V/F and F/V Converters(47)

- PMIC - Thermal Management(297)

- PMIC - Supervisors(17396)

- PMIC - RMS to DC Converters(555)

- PMIC - Power Supply Controllers, Monitors(723)

- PMIC - Power Over Ethernet (PoE) Controllers(368)

- PMIC - Power Management - Specialized(2708)

Select Language

Current Language

English

- English

- Deutsch

- Italia

- Français

- 日本語

- 한국의

- русский

- Svenska

- Nederland

- español

- Português

- polski

- Suomi

- Gaeilge

- Slovenská

- Slovenija

- Čeština

- Melayu

- Magyarország

- Hrvatska

- Dansk

- românesc

- Indonesia

- Ελλάδα

- Български език

- Afrikaans

- IsiXhosa

- isiZulu

- lietuvių

- Maori

- Kongeriket

- Монголулс

- O'zbek

- Tiếng Việt

- हिंदी

- اردو

- Kurdî

- Català

- Bosna

- Euskera

- العربية

- فارسی

- Corsa

- Chicheŵa

- עִבְרִית

- Latviešu

- Hausa

- Беларусь

- አማርኛ

- Republika e Shqipërisë

- Eesti Vabariik

- íslenska

- မြန်မာ

- Македонски

- Lëtzebuergesch

- საქართველო

- Cambodia

- Pilipino

- Azərbaycan

- ພາສາລາວ

- বাংলা ভাষার

- پښتو

- malaɡasʲ

- Кыргыз тили

- Ayiti

- Қазақша

- Samoa

- සිංහල

- ภาษาไทย

- Україна

- Kiswahili

- Cрпски

- Galego

- नेपाली

- Sesotho

- Тоҷикӣ

- Türk dili

- ગુજરાતી

- ಕನ್ನಡkannaḍa

- मराठी

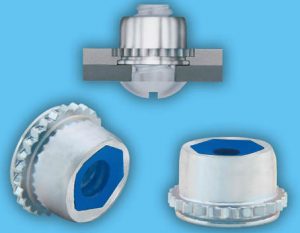

Press-in threaded insert includes locking

Time: January 4th, 2018

Browse: 639

“The reusable locking element provides the necessary torque resistance to securely grip mating screws and allow for their repeated installation and removal over time,” said Penn. “The primary advantage of this locking method is to greatly reduce the possibility of conductive debris being generated from repeated installation and removal of mating screws.”

Thread-locking torque performance is equivalent to applicable NASM25027 specifications.

Steel (PL) and stainless steel (PLC) versions install permanently in thin steel or aluminium sheets between l.0mm and 1.78mm thick. Shank lengths are .060” and 1.53mm.

Standard thread sizes are #4-40 to #10-32 and M3 to M5 – locking elements are black for metric versions and blue for US ‘unified’ threads.

Installation requires a press, during which locknut’s knurled collar embeds in the host sheet and displaces sheet material, which then fills the undercut cavity beneath the collar (see diagram) to captivate the fastener in the sheet.

“The strong knurled collar effectively receives the installation force and resists torque, exhibiting spin resistance greatly exceeding the torque exerted by the self-locking feature. Both the self-clinching shank of the locknut and the undercut contribute to high push-out values,” claimed Penn.

Penn Engineering makes products in the USA, Ireland and China.

Latest News

March 10th, 2025

March 6th, 2025

March 3th, 2025

February 27th, 2025

February 24th, 2025

February 20th, 2025

February 17th, 2025

February 13th, 2025

February 10th, 2025

February 7th, 2025