- Deutsch

-

EnglishDeutschItaliaFrançais日本語한국의русскийSvenskaNederlandespañolPortuguêspolskiSuomiGaeilgeSlovenskáSlovenijaČeštinaMelayuMagyarországHrvatskaDanskromânescIndonesiaΕλλάδαБългарски езикAfrikaansIsiXhosaisiZululietuviųMaoriKongeriketМонголулсO'zbekTiếng ViệtहिंदीاردوKurdîCatalàBosnaEuskeraالعربيةفارسیCorsaChicheŵaעִבְרִיתLatviešuHausaБеларусьአማርኛRepublika e ShqipërisëEesti Vabariikíslenskaမြန်မာМакедонскиLëtzebuergeschსაქართველოCambodiaPilipinoAzərbaycanພາສາລາວবাংলা ভাষারپښتوmalaɡasʲКыргыз тилиAyitiҚазақшаSamoaසිංහලภาษาไทยУкраїнаKiswahiliCрпскиGalegoनेपालीSesothoТоҷикӣTürk diliગુજરાતીಕನ್ನಡkannaḍaमराठी

A Guide to Instrumentation Amplifiers

- 2024/12/31

- 0

Catalog

What is an Instrumentation Amplifier?

An instrumentation amplifier is a type of integrated circuit (IC) primarily designed to amplify signals with precision. As a member of the differential amplifier family, it excels at amplifying the difference between two input signals while suppressing unwanted common-mode noise. Its design is centered around reducing excess noise that might otherwise degrade the signal, making it a preferred choice for precision measurement and electronic instrumentation.

One of its defining characteristics is its high common-mode rejection ratio (CMRR), which ensures noise immunity during operation. With features such as high open-loop gain, low drift, low DC offset, and excellent stability, instrumentation amplifiers are integral to circuits that demand accuracy and reliability in various environments.

Instrumentation Amplifier using Op-Amp

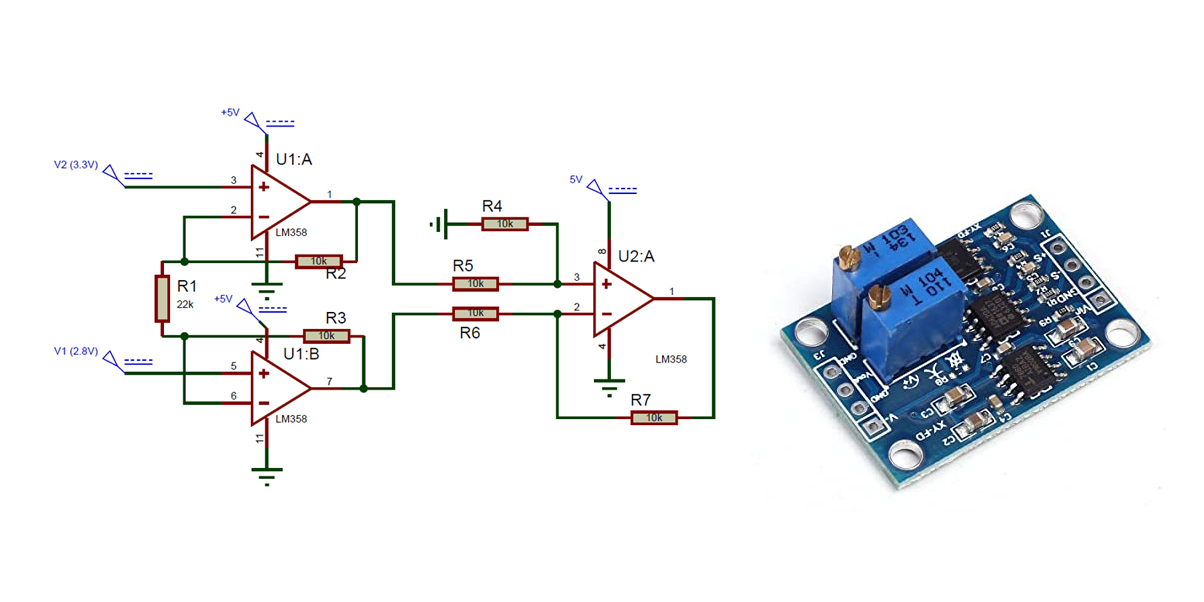

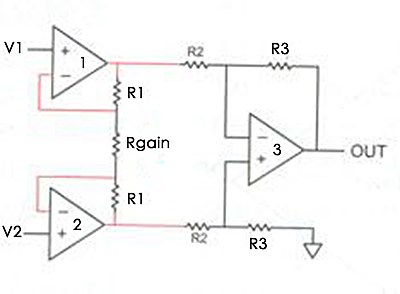

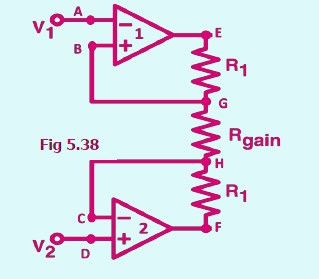

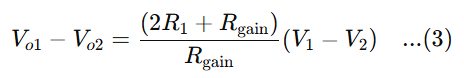

The instrumentation amplifier, constructed using operational amplifiers (op-amps), consists of three op-amps working in tandem. Op-amps 1 and 2 act as non-inverting amplifiers, while op-amp 3 functions as a differential amplifier. Together, these op-amps create a configuration that amplifies the differential input signals while rejecting common-mode signals. The output voltage of the instrumentation amplifier, Vout, is determined by the amplified difference between the input signals as applied to the input terminals of op-amp 3. If the outputs of op-amp 1 and op-amp 2 are Vo1 and Vo2, the output voltage can be expressed as:

Figure 2. Instrumentation Amplifier Circuit Using Three Op-Amps

In this setup, the input stage of the instrumentation amplifier plays a crucial role, as illustrated in the derivation below.

At node A, the potential is the input voltage V1. By the virtual short principle, the voltage at node B is also V1, which makes the potential at node G equal to V1 as well. Similarly, at node D, the potential is V2, and by the same principle, the voltage at node C is V2, making the potential at node H equal to V2.

Figure 3. Input Stage of the Instrumentation Amplifier

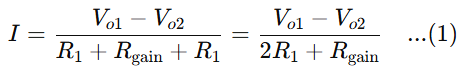

Ideally, in the input stage of the instrumentation amplifier, the current flowing into the op-amps is zero. Therefore, the current I through resistors R1, Rgain, and R1 remains constant. Applying Ohm’s Law between nodes E and F, the current I can be expressed as:

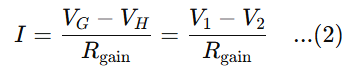

Since no current flows into the input of op-amps 1 and 2, the same current I flows between nodes G and H , which can be written as:

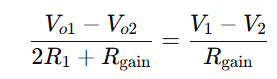

Equating equations (1) and (2), we get:

Simplifying further:

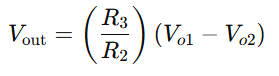

The differential amplifier, represented by op-amp 3, provides the output voltage Vout as:

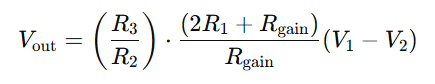

Substituting the expression for Vo1− Vo2 from equation (3) into the above equation, we get:

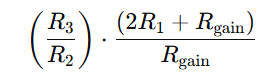

This final equation defines the output voltage of the instrumentation amplifier. The term:

Advantages of Instrumentation Amplifiers

Instrumentation amplifiers are highly reliable devices designed for applications requiring exceptional accuracy and stability. They offer high-gain, DC-coupled outputs while managing differential inputs and single-ended outputs. Their critical features include high input impedance, excellent common-mode rejection, low noise, minimal linearity error, and low offset voltage. These attributes, combined with low input bias current and minimal offset current, make them indispensable in precision measurement systems where signal integrity is paramount.

High Common-Mode Rejection Ratio (CMRR)

Instrumentation amplifiers are specifically designed to reject common-mode signals, such as noise or electromagnetic interference (EMI), while amplifying differential signals where input potentials vary. This is essential in scenarios involving microvolt-level differential signals contaminated by common-mode noise, which can span several volts. With typical CMRR values between 70 and 100 dB, these amplifiers ensure precise signal fidelity, particularly in noisy environments like medical diagnostics or industrial automation, where they excel in real-time monitoring.

Minimal Linearity Error

The linearity error of an instrumentation amplifier reflects the deviation between its actual output and the ideal linear response. High-performance instrumentation amplifiers achieve extremely low linearity errors, often as low as 0.01%, with some reaching an exceptional 0.0001%. This precision is vital in applications such as seismic monitoring and biomedical instrumentation, ensuring distortion-free and repeatable measurements even in fluctuating operational conditions, thereby maintaining the integrity of sensitive signals.

High Input Impedance

With input impedance values typically ranging from 109 to 1012 ohms, instrumentation amplifiers ensure minimal current draw from the signal source, preserving signal strength and accuracy. Their design enables precise matching between input terminals, reducing errors caused by impedance imbalance. This is critical when interfacing with delicate transducers like thermocouples or strain gauges, where any loading effect could compromise signal integrity, ensuring seamless and accurate signal processing during operations.

Low Noise

Instrumentation amplifiers operate effectively in noisy environments by maintaining low noise levels. For signals at frequencies around 1 kHz, the noise referred to the input is typically below 10 nV/√Hz, ensuring a high signal-to-noise ratio (SNR). This low noise performance is crucial in applications such as audio signal processing or medical monitoring, where maintaining clear and reliable signal outputs is essential for accurate analysis and operational efficiency.

Low Offset Voltage and Drift

Low offset voltage and minimal drift are critical factors in ensuring long-term stability and accuracy in instrumentation amplifiers. Typical input offset voltages are around 100 µV, with output offset values near 2 mV. These stable parameters minimize the need for recalibration, particularly in applications like environmental monitoring or long-term data acquisition. The high level of integration in these amplifiers reduces the complexity of circuit design, making them more efficient and reliable for precision applications requiring consistent and stable outputs.

Operational Amplifier vs. Instrumentation Amplifier

Operational amplifiers (op-amps) and instrumentation amplifiers are foundational components in electronics, each designed to fulfill specific roles. While they share some similarities in their basic operation, their differences are significant and critical to understand for selecting the right device in various applications. The distinctions between the two are detailed below:

Op-Amps as Active Amplifiers

Operational amplifiers are general-purpose, highly versatile integrated circuits. They are classified as active amplifiers and are the building blocks for a wide range of analog signal processing functions, including signal amplification, filtering, integration, differentiation, and mathematical operations. Their flexibility allows engineers to configure them for various tasks by combining external passive components. Op-amps excel in applications such as audio processing, signal conditioning, and analog computation. However, their performance in differential signal handling is limited by factors such as moderate CMRR and sensitivity to external resistor tolerances.

Instrumentation Amplifiers as Differential Amplifiers

Instrumentation amplifiers are a specialized type of differential amplifier, explicitly designed for precision measurement applications. They amplify small differential signals while rejecting large common-mode signals, making them indispensable in noise-sensitive environments. This capability is vital in scenarios like medical monitoring, strain gauge measurements, or temperature sensing, where signal accuracy and noise immunity are paramount. The operational advantage of instrumentation amplifiers lies in their ability to maintain performance under noisy conditions, often encountered in industrial and medical applications. Their internal design ensures stable operation, even in challenging environments.

Construction Differences

Instrumentation amplifiers are typically constructed using three operational amplifiers. This configuration is engineered to achieve:

• High Input Impedance: Prevents loading effects and preserves signal integrity.

• High CMRR: Enhances noise rejection capabilities.

• Precise Gain Control: Simplifies gain adjustments without affecting other parameters.

This three-op-amp architecture is particularly advantageous when working with low-level signals, as it ensures accurate amplification and minimizes noise interference. Conversely, a standard differential amplifier can be built using a single operational amplifier. While simpler in design, this configuration often suffers from reduced performance metrics, such as lower CMRR and increased sensitivity to resistor mismatches. These limitations make them less suitable for applications demanding high precision.

Impact of Resistor Matching

In differential amplifiers, the output voltage heavily depends on the matching of resistors within the circuit. Any mismatch can introduce significant errors, degrading the accuracy of the amplified signal. This reliance on precise resistor matching makes design and maintenance more challenging, especially in high-precision tasks. Instrumentation amplifiers address this limitation by achieving gain in their primary stage using a single gain-setting resistor. This design eliminates the need for closely matched resistors, reducing the impact of resistor mismatches on overall performance. As a result, instrumentation amplifiers simplify design considerations while delivering superior accuracy and consistency.

Applications of Instrumentation Amplifier (Upgraded Content)

Instrumentation amplifiers are critical components in applications that require high precision, stability, and immunity to noise. Their ability to deliver accurate differential gain, even under challenging conditions with large common-mode signals and significant electrical noise, makes them indispensable in various fields. Below are key applications, detailed with practical insights into their operations:

Data Acquisition from Small Output Transducers

Instrumentation amplifiers are widely employed to process signals from low-output transducers such as thermocouples, strain gauges, and Wheatstone bridge circuits. These devices typically produce weak signals that require precise amplification with minimal distortion or noise interference.

Applications in Navigation, Pharmaceuticals, and Radar Systems

The precision and reliability of instrumentation amplifiers make them suitable for use in critical applications such as navigation systems, pharmaceutical instruments, and radar technology. These systems involve complex and sensitive signal processing tasks requiring high accuracy and noise immunity.

Audio Signal Processing

Instrumentation amplifiers are used to amplify low-amplitude audio signals, significantly improving the signal-to-noise (S/N) ratio. This makes them essential in professional audio equipment, hearing aids, and recording systems.

High-Speed Signal Conditioning

For imaging and video data acquisition systems, instrumentation amplifiers play a critical role in high-speed signal conditioning. Their ability to handle fast-changing signals with minimal distortion ensures accurate image or video capture.

High-Frequency Signal Amplification in RF Networks

In radio frequency (RF) cable networks, instrumentation amplifiers are utilized to amplify high-frequency signals. Their precision and low noise characteristics ensure efficient signal transmission and minimal degradation over long distances.

Conclusion

Instrumentation amplifiers are crucial in modern electronics for their precision, reliability, and versatility. They amplify small signals while rejecting noise, making them essential for medical monitoring, data acquisition, and high-speed processing. With excellent noise immunity and long-term stability, they perform consistently in challenging environments. From audio systems to industrial automation, their robust design simplifies tasks and ensures precise results, making them a cornerstone in advanced technologies.

Frequently Asked Questions [FAQ]

1. How does an instrumentation amplifier work?

It works by amplifying the voltage difference between two input signals while suppressing signals that are common to both inputs, such as noise or interference.

2. What are the key features of an instrumentation amplifier?

Key features include high input impedance, high common-mode rejection ratio (CMRR), low noise, low offset voltage, low drift, and excellent stability.

3. What is the role of CMRR in an instrumentation amplifier?

CMRR, or common-mode rejection ratio, allows the amplifier to reject noise or interference signals that are common to both inputs, ensuring the amplified output is free from unwanted noise.

4. Why is high input impedance important in an instrumentation amplifier?

High input impedance prevents the amplifier from drawing significant current from the signal source, preserving signal integrity and avoiding loading effects.

5. How is gain controlled in an instrumentation amplifier?

Gain is typically controlled using a single resistor, known as the gain-setting resistor, making it easy to adjust without affecting other parameters.

Verwandter Blog

-

Netzteilspannung Abkürzung: VCC VDD VEE VSS GND

2024/06/6

Im modernen elektronischen Schaltungsdesign, Verständnis der Abkürzungen der Stromversorgungsspannung (wie VCC, VDD, VEE, VSS, GND).Diese Abkürzung... -

Ein Überblick über TTL- und CMOS -ICs und wie Sie zwischen ihnen wählen

2024/04/13

In diesem Artikel werfen wir einen detaillierten Blick auf zwei wichtige elektronische Technologien, komplementäre Metaloxid-Halbleiter (CMOS) und Tr... -

Verschiedene Arten von Sicherungen und Anwendungen

2024/04/18

Sicherungen sind wesentliche Komponenten in modernen elektrischen Systemen und fungieren als entscheidende Beschützer vor Überstrom.Sie arbeiten, in... -

Verständnis des C1815 -Transistors: Pinouts, Schaltungssymbole, Anwendungsschaltungen

2023/12/20

Welche Art von Röhre ist der C1815?C1815 Triode PinoutC1815 ModellzeichnungC1815 -ParameterC1815 EigenschaftenAnwendung von C1815 Der C1815 -Transist... -

LR44 -Batterien: LR44 -Batterieäquivalente und LR44 -Batterieersatz

2024/01/24

In einem sich schnell entwickelnden technologischen Gebiet, in dem die Größe der elektronischen Geräte weiter schrumpfen und dennoch alltäglicher ... -

Grundkenntnisse über Sicherungen: Merkmale, Arbeitsprinzipien, Typen und wie man richtig auswählt

2024/04/10

Sicherungen schützen Schaltungen vor Schäden aufgrund von Überlastung oder Kurzstrecken.Dieses einfache, aber geniale Gerät basiert auf einem leic... -

Leitfaden zu Buck-, Boost- und Buck-Boost-Konverter

2023/12/21

Was ist ein Buck -Konverter?Wie funktioniert ein Buck Converter?Was ist ein Boost -Konverter?Wie funktioniert ein Boost -Konverter?Was ist ein Auftrie... -

Gesamtzahl der Transistoren in einer CPU

2024/06/14

In der modernen Computertechnologie ist die Beziehung zwischen der zentralen Verarbeitungseinheit (CPU) und den Transistoren zunehmend integraler gewo... -

Beschreiben Sie kurz die Spezifikationen, Verpackungen, das Arbeitsprinzip, die Vorteile und die Umweltauswirkungen von Lithium-Ionen-Batterien

2024/03/20

Seit der Einführung von wiederaufladbaren Blei-Säure-Batterien im Jahr 1859 wurden sie allmählich in den Gewebe des technologischen Fortschritts ei... -

Grunde elektronische Grundkomponenten verstehen - Widerstände, Kondensatoren, Dioden, Transistoren, Induktoren und digitale Logik -Tore

2024/04/13

Elektronische Komponenten sind der Eckpfeiler des Bauens und der Optimierung elektronischer Schaltkreise.Von gewöhnlichen Haushaltsgeräten bis hin z... -

Beherrschen analoge und digitale Schaltungen: Ein Anfängerführer

2023/12/20

Definition und Eigenschaften von analogen Schaltungen und digitalen SchaltungenDer Unterschied zwischen analogen Schaltungen und digitalen Schaltungen... -

Transistor (BJT und MOSFET) Arbeitsprinzipien

2023/12/20

Arbeitsprinzip des bipolaren Junction -Transistors (BJT)Auswahl der KomponentenwerteWie wählen Sie einen Transistor?Arbeitsprinzip von MOSFETWie scha... -

Eine vollständige Liste von Testmethoden für verschiedene Transistoren

2023/12/20

Der Transistor wurde von John Bardeen, William Shockley und Walter Brattain erfunden.Es handelt sich um ein Kollektor-, Emitter- und Basis-Drei-termin...

Heiße Teile

- 08051C271K4T2A

- 06031U7R5CAT2A

- GRM21BC81H475ME11L

- TAJB475M010H

- T495C106K025ATE300

- TPD8S300RUKR

- J1011F21PNL

- IRF9530S

- GRM1555C1HR40BZ01D

- BNX016-01

- SRR4018-6R8Y

- EP3C80F484C7N

- CY8C27643-24LTXI

- LM5018MR/NOPB

- TMS320F28335PTPQ

- PIC32MZ2048EFH100-I/PF

- NUC123SD4AN0

- LTC4063EDD#TRPBF

- MC78LC33NTRG

- EY1501DI-ADJ

- UCD7100PWPR

- VE-J02-MY

- N370CH16KOO

- LM78H24K

- PF38F3040M0Y3DFA

- STLC2593TR

- TPS2205IDBRG4

- BSC035N04NS3G

- UPD78F1840AGKA-GAK-G

- R8A77404PBG#U0

- MD5832-D256-V3Q18-X

- GT48330-PBE1

- T491C155M050AT

- T494B685M010AT

- T491B476M006ZT7111ZV18

- GPC110330-HL011

- LTC2602CMS8

- TC55257DFL-70L-EL

- G5322F61U

- MSC1673-03

- SAB82538H-10

- EGLXT915QC

- V54C365164VCT8PC

- SPV9202B3-S

- PC414455VR

- TPS548B22RVF

- NX30P0121UK

- DW3220