- Deutsch

-

EnglishDeutschItaliaFrançais日本語한국의русскийSvenskaNederlandespañolPortuguêspolskiSuomiGaeilgeSlovenskáSlovenijaČeštinaMelayuMagyarországHrvatskaDanskromânescIndonesiaΕλλάδαБългарски езикAfrikaansIsiXhosaisiZululietuviųMaoriKongeriketМонголулсO'zbekTiếng ViệtहिंदीاردوKurdîCatalàBosnaEuskeraالعربيةفارسیCorsaChicheŵaעִבְרִיתLatviešuHausaБеларусьአማርኛRepublika e ShqipërisëEesti Vabariikíslenskaမြန်မာМакедонскиLëtzebuergeschსაქართველოCambodiaPilipinoAzərbaycanພາສາລາວবাংলা ভাষারپښتوmalaɡasʲКыргыз тилиAyitiҚазақшаSamoaසිංහලภาษาไทยУкраїнаKiswahiliCрпскиGalegoनेपालीSesothoТоҷикӣTürk diliગુજરાતીಕನ್ನಡkannaḍaमराठी

Erforschung der strukturellen Kabelstruktur und Funktionen von Koaxialkabeln

- 2024/11/4

- 412

Katalog

Verständnis des Koaxialkabels

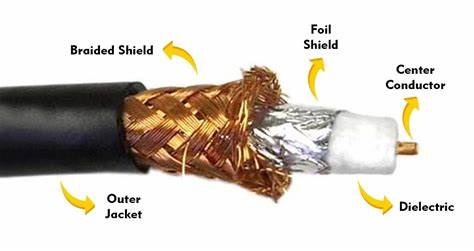

Ein Koaxialkabel wird verwendet, um effizient hochfrequente elektrische Signale zu übertragen und gleichzeitig den Signalabbau und die Interferenz zu minimieren.Die Struktur eines Koaxialkabels ist sorgfältig ausgelegt und besteht aus vier wesentlichen Schichten, wobei jeweils eine bestimmte Funktion dient, um eine optimale Leistung zu gewährleisten.

Erstens liegt im Kern eines Koaxialkabels die Innenleiter, Normalerweise aus festem oder gestrandetem Kupfer.Dieses zentrale Element trägt die elektrischen Signale und ist für die Hauptfunktion des Kabels der Datenübertragung von wesentlicher Bedeutung.Um diesen Kern umzugeben ist der Isolierschicht, ein dielektrisches Material, das verhindert, dass elektrische Energie aus dem inneren Leiter entkommt.Materialien wie Polyethylen oder Teflon werden hier üblicherweise verwendet, um die Signalintegrität zu verbessern und sicherzustellen, dass das elektrische Feld fest bleibt.

Die dritte Schicht, das Netz genannt Schildschicht, ist typischerweise ein geflochtenes oder mit Folie umgetriebenes Metall wie Kupfer oder Aluminium.Diese Schicht wirkt als Schutzbarriere gegen elektromagnetische Interferenzen (EMI) aus externen Quellen.Es verhindert auch, dass das Kabel sich wie eine Antenne verwirkt, die das von ihm trägt versehentlich versehentlich übertragene Signal übertragen könnte, was zu Datenverlust führen würde.Schließlich wird die gesamte Baugruppe von der Außenbedeckung bedeckt Isolierschicht, normalerweise aus haltbaren und flexiblen Materialien wie PVC oder Teflon, die die inneren Schichten vor physischen Schäden, Feuchtigkeit und Verschleiß schützen.

Die Kombination dieser vier Schichten stellt sicher, dass Koaxialkabel sowohl analoge als auch digitale Signale zuverlässig übertragen können, was sie zu einer hervorragenden Wahl für verschiedene Anwendungen macht, einschließlich Kabelfernsehernetzwerke, Internetverbindungen und sogar bestimmter Computer -Netzwerk -Setups.Durch das Einschließen des Signalwegs in eine robuste, abgeschirmte Struktur bieten Koaxialkabel in Umgebungen, in denen die Signalqualität von größter Bedeutung ist, eine überlegene Leistung.

Arten von Koaxialkabeln

Koaxialkabel werden in Basisband- und Breitbandvarianten unterteilt, die jeweils zugeschnitten sind, um einzigartige Kommunikationsziele zu erfüllen und unterschiedliche technische Funktionen zu bieten.

Basisband Koaxialkabel

Es wird am häufigsten zur Übertragung digitaler Signale verwendet.Es verfügt über eine Kupfer -Mesh -Abschirmung und hat im Allgemeinen eine charakteristische Impedanz von 50 Ohm.Die beiden häufigsten Varianten von Basisbandkabeln sind RG-8 und RG-58.RG-8, oft als "dickes Kabel" bezeichnet, ist für seine robusten Build- und Langstreckenfunktionen bekannt, wodurch es für mittelgroße lokale Netzwerke (LANs) geeignet ist.Seine Größe und Steifigkeit machen die Installation jedoch komplexer und teurer.Im Gegensatz dazu ist RG-58 oder "dünnes Kabel" flexibler und einfacher zu installieren, obwohl es beim Schneiden und Anschließen Präzision erfordert, um den Signalabbau von schlechten Kontakten zu verhindern.Basisband -Koaxialkabel sind ideal für kleinere Computernetzwerke und digitale Datenübertragung in kontrollierten Umgebungen.

Breitband -Koaxialkabel

Es ist für die analoge Signalübertragung ausgelegt und hat typischerweise eine Impedanz von 75 Ohm, wobei RG-59 das am häufigsten verwendete Modell ist.RG-59 ist ein Grundnahrungsmittel in der Kabelfernseherbranche, da es mehrere Fernsehkanäle über große Strecken durch ein einzelnes Kabel tragen kann.Diese Fähigkeit macht Breitband -Koaxialkabel in Anwendungen wertvoll, bei denen große Mengen an Informationen effizient übertragen werden müssen.Darüber hinaus verwenden einige spezialisierte Computernetzwerke auch Breitband-Koaxialkabel für Hochgeschwindigkeitsdatenübertragungen, obwohl sie sich mit zunehmender Konkurrenz durch Glasfaser-Optik und drahtlose Technologien konfrontieren.

Struktur- und Arbeitsprinzip von Koaxialkabeln

Der Betrieb eines Koaxialkabels hängt von seinem einzigartigen strukturellen Design ab.Der Begriff "koaxial"Bezieht sich auf die Ausrichtung der inneren und äußeren Leiter entlang derselben Achse. Diese Anordnung stellt sicher, dass das elektromagnetische Feld, das das Signal trägt, vollständig in der Isolierschicht enthalten und vom äußeren Leiter abgeschirmt ist, was die Interferenz beseitigt und die Signalintegrität aufrechterhält.

Wenn ein Signal durch den inneren Kupferleiter fährt, erzeugt es ein elektromagnetisches Feld.Die dielektrische Schicht isoliert dieses Feld, während die umgebende Maschenschichtschicht alle externen elektromagnetischen Wellen blockiert, die die Übertragung beeinträchtigen könnten.Dieser Abschirmmechanismus ist wirksam, wenn die äußere Schicht geerdet ist, da sie unerwünschte elektrische Störungen absorbiert und neutralisiert.Das Design verhindert auch, dass der innere Leiter elektromagnetische Signale in die Umgebung ausstrahlt, was die Datensicherheit beeinträchtigen und zum Signalverlust beitragen könnte.

Das Isoliermaterial zwischen den inneren und äußeren Leitern spielt eine entscheidende Rolle bei der Erhaltung eines gleichmäßigen Abstands zwischen ihnen.Jede Abweichung in diesem Abstand kann die Impedanz des Kabels stören und Signalreflexionen verursachen, die die Übertragungsqualität schwächen.Infolgedessen sind Koaxialkabel relativ steif und können keine scharfen Biegungen oder einen signifikanten Druck tolerieren, ohne dass die Leistungsverschlechterung gefährdet.

Funktionen und Fortschritte in der Koaxialkabeltechnologie

Koaxialkabel verfügen über eine charakteristische Architektur mit einem zentralen Kupferleiter, der in einer isolierenden Kunststoffschicht, einem leitenden Netz und einer äußeren Hülle eingeschlossen ist.Im Gegensatz zu seinem direkten Gegenstück wechselt es die Richtung mehrmals pro Sekunde und spielt eine wichtige Rolle bei der Übertragung von Hochfrequenzsignalen.Die abwechselnden Ströme dienen dieser Funktion so effektiv.Ihre Fähigkeit ist es, Verluste zu minimieren und die Signalkonsistenz aufrechtzuerhalten, die sowohl für spezialisierte als auch für den Alltag unverzichtbar ist.Das Design begrenzt von Natur aus die Funkwellenemission, indem sie die elektromagnetische Strahlung innerhalb des leitenden Netzes einschränken und die Konservierung der Signaltreue gewährleistet.Dieser Aspekt ist das, was Telekommunikationsexperten für unschätzbare und beruhigende konsistente Signalintegrität für zahlreiche Geräte finden und so die praktischen Grundlagen dieser Technologie veranschaulichen.

Eine der wichtigen Komponenten ist der isolierende Kunststoff, das die interne Signalreflexion abweist, die durch Kabelbiege oder Kompression induziert wird, indem eine feste Trennung zwischen dem zentralen Leiter und dem äußeren Netz aufrechterhalten wird.Dieser Schutz verringert zwar effektiv, und verringert zwar die Flexibilität des Kabels und stellt eine häufige Herausforderung bei Installationen, bei denen angenommen wird, dass die Präzisionsbehandlung potenzielle Probleme umgeht.Es hat moderne Innovation mit dieser Starrheit.In der Tat haben Fortschritte wie das Schichten in der Abschirmtechnologie den Signalschutz deutlich gestärkt und die Gesamtleistung erhöht, was die Nutzung in verschiedenen Umgebungen ermöglicht, ohne die Qualität zu beeinträchtigen.Diese Progression beleuchtet ein faszinierendes Zusammenspiel zwischen Design -Feinheiten und ihren Anwendungen, um die Streben nach überlegenen Leistungsstandards zu erreichen.

Vorteile und Herausforderungen von Koaxialkabeln

Koaxialkabel bieten mehrere bemerkenswerte Vorteile. Erstens unterstützen sie die Kommunikation mit hoher Bandbreite Über lange Entfernungen ohne die Notwendigkeit von Signalrepoatern, was sie zu einer effizienten Wahl für die Übertragung großer Datenmengen macht.Die umfangreiche Abschirmung, die durch die Netzschicht bereitgestellt wird sorgt für minimale Einmischung aus externen Quellen, was in Umgebungen mit mehreren elektronischen Geräten von entscheidender Bedeutung ist.Die Kabel sind auch für ihre robuste und zuverlässige Leistung bekannt, wodurch sie sowohl für Innen- als auch für Außenanwendungen geeignet sind.

Koaxialkabel sind jedoch auch mit einigen Nachteilen ausgestattet.Eine der primären Nachteile sind ihre Masse.Sogar die dünneren Varianten wie RG-58 sind im Vergleich zu anderen Kommunikationskabeln relativ dick benötigen mehr physischen Raum für die Installation.Die Steifigkeit der Kabel erschwert ihren Einsatz weiter, da sie sich nicht leicht um Ecken biegen oder in enge Räume passen können.Zusätzlich sind Koaxialkabel in der Regel teurer als Alternativen wie verdrehte Paarkabel, sowohl in Bezug auf die materiellen Kosten als auch die Komplexität der Installation.

Auswahl zwischen Koaxialkabeln und gewöhnlichen Kabeln

Beim Vergleich von Koaxialkabeln mit gewöhnlichen elektrischen Kabeln werden mehrere Unterscheidungen offensichtlich.Koaxialkabel werden mit einem Kupferkern konstruiert, der von Isolier- und Abschirmschichten umgeben ist, sodass sie hochfrequente Signale mit minimalem Verlust übertragen können.Normale Kabel dagegen bestehen typischerweise aus mehreren miteinander gebündelten Drähten und für einfachere und niedrigere Frequenz-elektrische Verbindungen.

In Bezug auf die Klassifizierung werden Koaxialkabel basierend auf ihren Signalübertragungsfunktionen in Basisband- und Breitbandtypen unterteilt.Gewöhnliche Kabel können jedoch in Art und Zweck variieren, einschließlich Stromkabeln, flammretardanten Kabeln und sogar optischen Fasern für moderne Kommunikationssysteme.Diese Variation spiegelt den breiteren Anwendungsbereich und eine einfachere Konstruktion wider, die für gewöhnliche Kabel typisch ist.

Leistungsmetriken von Koaxialkabeln

Die Leistung und Effizienz von Koaxialkabeln werden durch mehrere Parameter definiert, die beeinflussen, wie Signale übertragen werden und wie gut das Kabel unter verschiedenen Bedingungen funktioniert.Verständnis dieser Parameter zur Auswahl des richtigen Koaxialkabels für bestimmte Anwendungen, sei es in Telekommunikations-, Rundfunk- oder Datennetzen.

Charakteristische Impedanz: Eine der wichtigsten elektrischen Eigenschaften eines Koaxialkabels, die charakteristische Impedanz wird in Ohm (ω) gemessen und repräsentiert den Widerstand gegen den Fluss eines abwechselnden Stromsignals.Für Koaxialkabel sind die gemeinsamen Impedanzwerte 50 Ω und 75 Ω, die basierend auf der beabsichtigten Anwendung ausgewählt wurden.Eine konsistente Impedanz entlang der Kabellänge ist von entscheidender Bedeutung, um Signalreflexionen zu minimieren und eine effiziente Signalübertragung zu gewährleisten.Impedanzfehlanpassungen können zu Stromverlust und Signalverzerrungen führen.

Dämpfung: Die Dämpfung bezieht sich auf den Verlust der Signalstärke, wenn sie durch das Kabel wandert, gemessen in Dezibel (dB) pro Länge der Einheit (z. B. dB pro Meter oder dB pro Kilometer).Die Dämpfung nimmt mit Häufigkeit zu;Daher erleben höhere Frequenzen mehr Verluste.Das Design des Kabels, einschließlich der Auswahl von dielektrischem Material und Abschirmqualität, wirkt sich auf die Abschwächungsniveaus aus.Minimierung der Abschwächung der Übertragung von Fern- und Hochfrequenzsignalen, da übermäßiger Verlust die Signalqualität beeinträchtigen kann.

Ausbreitungsgeschwindigkeit: Die Geschwindigkeit, mit der ein elektrisches Signal durch das Koaxialkabel wandert, das häufig als Prozentsatz der Lichtgeschwindigkeit (c) ausgedrückt wird.Diese Geschwindigkeit hängt von der Dielektrizitätskonstante des Isolationsmaterials ab.Beispielsweise bieten Kabel mit niedrig dielektrischen Materialien wie Teflon oder luftunsillierten Konstruktionen höhere Ausbreitungsgeschwindigkeiten, was zu einer schnelleren Datenübertragung und einer verringerten Signalverzögerung führt.Typische Ausbreitungsgeschwindigkeiten liegen zwischen 66% und 95% der Lichtgeschwindigkeit.

Kapazität : In Picofarads pro Meter (PF/M) gemessen, stellt die Kapazität die Fähigkeit des Kabels dar, eine elektrische Ladung zu speichern.Eine niedrigere Kapazität wird im Allgemeinen für Hochfrequenzanwendungen bevorzugt, da sie das Potenzial für eine Signalverzerrung verringert und eine bessere Signalqualität gewährleistet.Das dielektrische Material und die Konstruktion des Kabels beeinflussen seine Kapazität.

DC -Schleifenwiderstand: Dies misst den Gesamtwiderstand sowohl der inneren als auch der äußeren Leiter auf Gleichstrom, typischerweise in Milliohm pro Meter angegeben.Ein niedriger DC -Schleifenwiderstand ist wünschenswert, da er weniger Energieverlust angibt, wenn das Kabel für die Stromübertragung oder das Tragen elektrischer Signale verwendet wird.Ein hoher Widerstand kann zu Erhitzen und einer verringerten Leistung führen, insbesondere über längere Strecken.

Wirksamkeit der Abschirmung: Die Fähigkeit der Abschirmung des Koaxialkabels, elektromagnetische Interferenzen (EMI) aus externen Quellen zu blockieren.Eine effektive Abschirmung stellt sicher, dass das Signal innerhalb des Kabels frei von Geräuschen bleibt und dass das Kabel keine Signale ausgibt, die die elektronischen Geräte in der Nähe beeinträchtigen könnten.Die Abschirmwirksamkeit hängt vom Material und der Konstruktion des Schildes ab, mit Optionen wie geflochtenem Draht, Folie oder einer Kombination aus beiden Schutzniveaus.

Eigenschaften verschiedener dielektrischer Materialien in Koaxialkabeln

Koaxialkabel zeigen Variationen der Draht- und Kerndurchmesser, Leiter- und Isolationsmaterialien sowie Hüllestrukturen.Diese Parameter beeinflussen gemeinsam die elektrische Leistung, die mechanische Integrität und die Eignung des Kabels.

Auswirkungen auf die Kabelverzögerung und die Ausbreitungsgeschwindigkeit

Der dielektrische Isolator (Dielektrikum) ist eine kritische Komponente, die sowohl die Verzögerung als auch die Ausbreitungsgeschwindigkeit des Koaxialkabels beeinflusst.Zu den häufigen dielektrischen Materialien gehören fester Polyethylen (PE), Polyethylenschaum (PF), luftunsilliertes Polyethylen (ASP), FoMamed Polystyrol (FS), fester Teflon (Polytetrafluorethylen, PTFE) und luftinseliger Teflon (AST).Die folgende Tabelle fasst den Einfluss dieser Materialien auf die Kabelverzögerung und die Ausbreitungsgeschwindigkeit zusammen.

|

Dielektrikum

Material |

Wirkung

Bei Verzögerung |

Vermehrung

Geschwindigkeit |

|

Solide

Polyethylen (PE) |

Mäßige Verzögerung |

66% des Lichts

Geschwindigkeit |

|

Polyethylen

Schaum (PF) |

Reduzierte Verzögerung |

80% des Lichts

Geschwindigkeit |

|

Luftunuliert

Polyethylen (ASP) |

Minimale Verzögerung |

99% des Lichts

Geschwindigkeit |

|

Geschliffen

Polystyrol (FS) |

Geringe Verzögerung |

90% des Lichts

Geschwindigkeit |

|

Solide Teflon

(PTFE) |

Sehr geringe Verzögerung |

92% des Lichts

Geschwindigkeit |

|

Luftunuliert

Teflon (AST) |

Vernachlässigbare Verzögerung |

99% des Lichts

Geschwindigkeit |

Anwendbare Arbeitstemperatur von isolierenden mittleren und äußeren Haut

Der Arbeitstemperaturbereich des Isoliermediums und der äußeren Hülle bestimmt die Betriebsumgebung des Kabels.Die folgende Tabelle bietet einen Überblick über diese Temperaturgrenzen.

|

Materialtyp |

Arbeitstemperaturbereich |

|

Ptee |

-75 ° C ~ +250 ° C. |

|

Pe |

-65 ° C ~ +80 ° C. |

|

FPE |

-65 ° C ~ +80 ° C. |

|

Schaum- oder feste Ethylen -Propylenscheide |

-40 ° C ~ +105 ° C. |

|

Fep |

-70 ° C ~ +200 ° C. |

|

PVC |

-50 ° C ~ +85 ° C. |

|

Ectfe |

-65 ° C ~ +150 ° C. |

|

Polyurethan |

-100 ° C ~ +125 ° C. |

|

PFA |

-65 ° C ~ +260 ° C. |

|

Nylon |

-60 ° C ~ +120 ° C. |

|

Ethylenpropylen |

-40 ° C ~ +105 ° C. |

|

Polyethylen mit hohem Molekulargewicht |

-55 ° C ~ +85 ° C. |

|

Verbranntes Polyolefin |

-40 ° C ~ +105 ° C. |

|

Silikonkautschuk |

-70 ° C ~ +200 ° C. |

|

Silikongesättiger Glasfaser |

-70 ° C ~ +250 ° C. |

|

Hochtemperatur -Nylonfaser |

-100 ° C ~ +250 ° C. |

Überlegungen zur Kabelmantelmaterial

- Flexibler thermoplastisches Gummi (TPR): Wenn das Kabel um ein Objekt eingewickelt werden muss, wird TPR für seine Flexibilität empfohlen.Vermeiden Sie jedoch häufige Bewegungen, um die Leistungsintegrität aufrechtzuerhalten.

- Flammretardante aufrechte Kabel (CMR): Für die Verwendung in Aufzügen, in denen der Flammenwiderstand von entscheidender Bedeutung ist, wählen Sie aufrechte Kabel, die eine Brandverbreitung verhindern und Standardmaterialien von Standard -Polyethylen vermeiden.

- Mezzanine Cable (CMP): Für versteckte Installationen innerhalb von Gebäuden ist CMP mit Teflon -Wechsel ideal, da die Kabelverstriche minimiert und im Falle eines Brandes eine geringe Toxizität erzeugt.

- PVC- oder TPR -Kabelscheide: Wenn Kabel extern oder entlang der Bürodecke weiterleiten, kann PVC oder TPR die Flexibilität verbessern, ohne den Einfügungsverlust erheblich zu erhöhen.

- Fluoriertes Ethylenpropylen (FEP) Sandwichkabel: Diese Art von Kabel kombiniert niedrige Verluste Eigenschaften mit hohem Temperaturwiderstand, wodurch es für anspruchsvolle Anwendungen geeignet ist.

Häufig gestellte Fragen [FAQ]

1. Wofür wird Koaxialkabel verwendet?

Koaxialkabel wird von Kabelbetreibern, Telefonunternehmen und Internetdienstanbietern häufig verwendet, um Daten, Video- und Sprachkommunikation an Kunden zu übertragen.Es wird auch häufig in Wohngebieten verwendet.

2. Gibt es verschiedene Arten von Koaxialkabeln?

Ja, es gibt zwei primäre Arten von Koaxialkabeln, die auf Impedanz basieren: 75 Ohm (ω) und 50 Ohm (ω).Kabel mit einer Impedanz von 75 Ohm werden normalerweise für Videosignale verwendet, während 50 Ohm Kabel für die Datenübertragung und die drahtlose Kommunikation bevorzugt werden.

3. Ist Coax Cable genauso wie TV -Kabel?

Ja, das für den Kabel Internetdienst verwendete Koaxialkabelnetz entspricht dem für Kabelfernsehen.Ihr Internetdienstanbieter überträgt Datensignale über das Koaxialkabel in Ihr Zuhause, insbesondere in Ihr Modem.

4. Welches Koaxialkabel eignet sich am besten für digitales Fernsehen?

Das RG6-Koaxialkabel eignet sich ideal zum Anschließen eines Fernsehgeräts oder einer Set-Top-Box mit einer Fernseher-, Satellitenschüssel oder einem Satellitenempfänger.Es ist auch für Internet- und digitale Videoanwendungen geeignet.RG6-Kabel bieten eine verbesserte Abschirmung und eine 75-Ohm-Impedanz, wodurch sie zum Tragen von GHZ-Signalen effektiver werden.

5. Ist Koaxkabel für die Internetnutzung geeignet?

Ja, die Investition in ein hochwertiges Koaxialkabel kann Ihre Internetverbindungsgeschwindigkeit verbessern, indem Sie den Signalverlust minimieren und die Interferenz von Funkfrequenzen blockieren, um eine stabilere Verbindung zu gewährleisten.

Verwandter Blog

-

Netzteilspannung Abkürzung: VCC VDD VEE VSS GND

2024/06/6

Im modernen elektronischen Schaltungsdesign, Verständnis der Abkürzungen der Stromversorgungsspannung (wie VCC, VDD, VEE, VSS, GND).Diese Abkürzung... -

Ein Überblick über TTL- und CMOS -ICs und wie Sie zwischen ihnen wählen

2024/04/13

In diesem Artikel werfen wir einen detaillierten Blick auf zwei wichtige elektronische Technologien, komplementäre Metaloxid-Halbleiter (CMOS) und Tr... -

Verschiedene Arten von Sicherungen und Anwendungen

2024/04/18

Sicherungen sind wesentliche Komponenten in modernen elektrischen Systemen und fungieren als entscheidende Beschützer vor Überstrom.Sie arbeiten, in... -

Verständnis des C1815 -Transistors: Pinouts, Schaltungssymbole, Anwendungsschaltungen

2023/12/20

Welche Art von Röhre ist der C1815?C1815 Triode PinoutC1815 ModellzeichnungC1815 -ParameterC1815 EigenschaftenAnwendung von C1815 Der C1815 -Transist... -

LR44 -Batterien: LR44 -Batterieäquivalente und LR44 -Batterieersatz

2024/01/24

In einem sich schnell entwickelnden technologischen Gebiet, in dem die Größe der elektronischen Geräte weiter schrumpfen und dennoch alltäglicher ... -

Leitfaden zu Buck-, Boost- und Buck-Boost-Konverter

2023/12/21

Was ist ein Buck -Konverter?Wie funktioniert ein Buck Converter?Was ist ein Boost -Konverter?Wie funktioniert ein Boost -Konverter?Was ist ein Auftrie... -

Grundkenntnisse über Sicherungen: Merkmale, Arbeitsprinzipien, Typen und wie man richtig auswählt

2024/04/10

Sicherungen schützen Schaltungen vor Schäden aufgrund von Überlastung oder Kurzstrecken.Dieses einfache, aber geniale Gerät basiert auf einem leic... -

Gesamtzahl der Transistoren in einer CPU

2024/06/14

In der modernen Computertechnologie ist die Beziehung zwischen der zentralen Verarbeitungseinheit (CPU) und den Transistoren zunehmend integraler gewo... -

Wie viele Spannungen sollte eine Autokatterie haben?

2024/08/25

Ist es wirklich genug zu sagen, dass eine Batterie bei 11,9 Volt oder höher "vollständig aufgeladen" ist?Diese Zahl bietet eindeutig eine Grundlinie... -

Grunde elektronische Grundkomponenten verstehen - Widerstände, Kondensatoren, Dioden, Transistoren, Induktoren und digitale Logik -Tore

2024/04/13

Elektronische Komponenten sind der Eckpfeiler des Bauens und der Optimierung elektronischer Schaltkreise.Von gewöhnlichen Haushaltsgeräten bis hin z... -

Beschreiben Sie kurz die Spezifikationen, Verpackungen, das Arbeitsprinzip, die Vorteile und die Umweltauswirkungen von Lithium-Ionen-Batterien

2024/03/20

Seit der Einführung von wiederaufladbaren Blei-Säure-Batterien im Jahr 1859 wurden sie allmählich in den Gewebe des technologischen Fortschritts ei... -

Beherrschen analoge und digitale Schaltungen: Ein Anfängerführer

2023/12/20

Definition und Eigenschaften von analogen Schaltungen und digitalen SchaltungenDer Unterschied zwischen analogen Schaltungen und digitalen Schaltungen... -

Transistor (BJT und MOSFET) Arbeitsprinzipien

2023/12/20

Arbeitsprinzip des bipolaren Junction -Transistors (BJT)Auswahl der KomponentenwerteWie wählen Sie einen Transistor?Arbeitsprinzip von MOSFETWie scha...

Heiße Teile

- 1206AA470KATBE

- 770680-1

- ISL9V3040S3ST

- AD977ABRSZ

- XC9536XL-7VQ44C

- TMS320DM8147SCYE1

- HD64F3664HV

- MB89191APF-G-608-ER-RE1

- HIN202ECBN-T

- MAX3096CSE

- CY7C109D-10VXI

- TPS7A7300RGWR

- V375C12C150BL

- VI-JT1-IY

- M27C4002-12F1

- TPS53317RGBT

- RT1206BRD07750KL

- 1MBH65D-090A

- 6MBP100RTD060

- AD7829BR

- CY22388ZXC-25T

- DS3501U+TR

- YSS216B-F

- LT1116CS8

- STC12C5410AD-35I-SOP28G

- LM4890ITLX

- UG10488B

- BCM2157B0KFBG

- PMB5745P10

- TNETA1545

- SC505820CFUB8

- 74VHC86FT(BE)

- VC0858SUNB

- KAG00K007A-DGG5

- TDA8029HL

- MAX3761EEP+T

- IRM-15-5

- GAL22V10B-15HJ

- TG1G-S035NY

- R5F-21334ANFP

- UPD703210YGC-105-8BT

- HYE18M256160CF-7.5

- LPC54002J512UK49

- M88CS8001-T030-A0D

- S34ML02G200BHI00X

- RT0603FRE131KL

- D1265C5

- INA226AIDGS